-40%

Rebuilt 2.5" Davis Standard Thermatic Extruder

$ 28509.35

- Description

- Size Guide

Description

Fully Rebuilt 2.5 InchDavis Standard Thermatic

Extruder

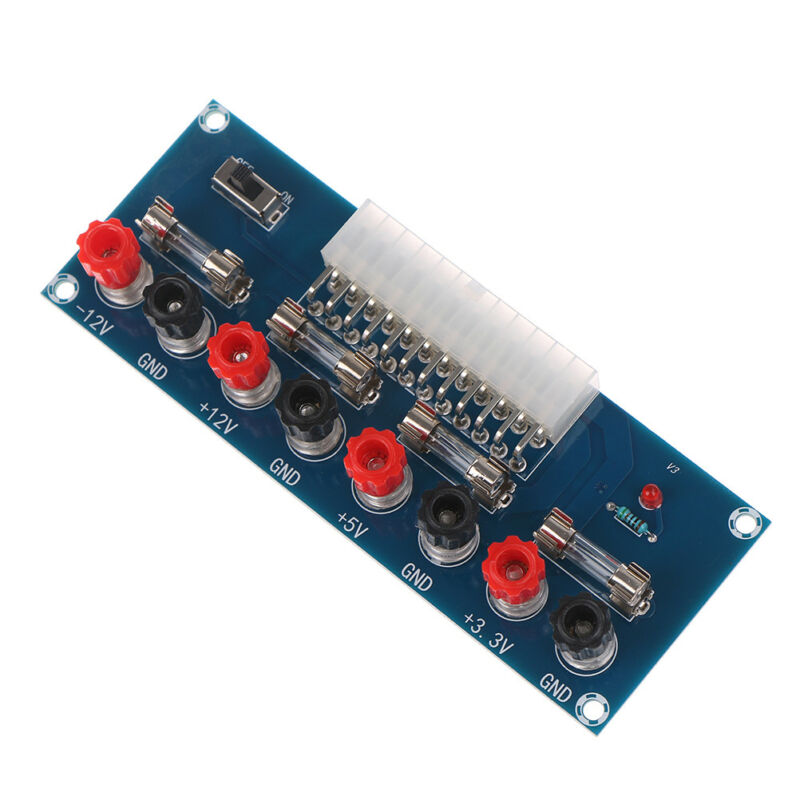

480/3/60 @ 125 Amp Machine Mounted Control Panel housing the following:

Serial # E2809

1.

QTY (4) HEAT/COOL barrel zones and QTY (4) HEAT/ONLY die zones, including Solid State, Circuit Breaker protection, all associated wiring and thermocouples, AMS Auto-tune temperature controllers.

2.

Motor STOP/START station, w/Screw RPM, Motor Amp Display and ten turn potentiometer for RPM control

3.

New WEGF 40 HP AC Vector Motor

4.

40HP AC Vector Motor Control

5.

Rebuilt Double Reduction Gearbox

6.

QTY (4) Barrel Blowers for Cooling

7.

Cast or Ceramic Barrel Heaters

8.

Gefran Digital Melt Pressure/ Temperature Display.

9.

Panel to be rotated 90 Degrees to allow operator access downstream from exit

side of cross head dies.

10.

480 VAC to 240 VAC step down transformer for all Die Zones

Mechanical Specifications and Hardware include the Following:

1.

20 to 1 Bi-metallic Barrel with 666 liner

2.

20 to 1 Barrier Maddoch Extrusion screw FPVC. Spare screw double flight for FPVC

Designed for run PP and PE.

3.

Heated Clamp quick change of Breaker plate, and tooling adaptors

4.

Stainless Steel Hopper Approximately 250 LBS

5.

Machine to be geared 0-120 Screw RPM

6.

10000 PSI Rupture Disc & Breaker Plate

7.

Frame Mounted Control Panel

8.

New High Temperature Insulation and steel barrel cover

9.

Extrusion Die Support Swing Arm to Hold Crosshead tooling.

10.

Water cooled Cast feed section.

11.

Qty (2) ports at end of barrel for pressure transducer and rupture disc.

Contact us for Lead Time to Completion.

Inquire with us about any of your extrusion equipment needs.

We have experts on staff to help you select the appropriate equipment to meet your manufacturing requirements!

Serious buyers please reach out to receive a full formal quotation or inquire with additional machine capability

Inspections welcome prior to purchase

Buyer is responsible for freight and crating fees

AMS specializes in offering cost-effective extrusion equipment; from high-quality rebuilds to new design innovations.

We welcome visitors to visit our facility in sunny West Palm Beach, Florida!